Maintaining clean fiber optic cable connections is a vital part of any network installation, but proper cleaning is often overlooked. Check out the 5 facts below, and then make sure you think twice before making a connection without ensuring that your connector’s end faces are clean:

#1 - Improper Cleaning Of Fiber Optic Cable Connections

Improper cleaning of fiber optic cable connections is the number one cause for network failures and contractor call-backs. USCONEC, a leader in providing passive components for high density optical interconnects, indicates that 80% of network owners and 98% of fiber optic cable installers cite contamination as the root cause of network failures. The use of dry cleaning tapes is recommended for single and multi-fiber ferrule connectors. Dry cleaning tape sticks and swabs, used with non volatile optical cleaning fluids, are acceptable for cleaning optical ports. Note that this recommendation does not include expanded beam lens (EBL) connectors or other connectors that may have anti-reflection coatings that require other special cleaning techniques.

#2 - You Can't Judge Fiber Optic Cleanliness With the Naked Eye

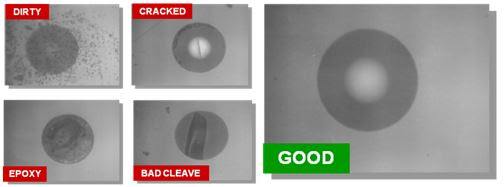

Your fiber optics cable isn’t clean, even if it appears to be with a naked eye. A dust particle, as small as one micrometer, can block up to one percent of the transmitted light through the fiber optics cable connector. A speck of dust as small as nine micrometers is still too small to see without a microscope, but it can completely block the fiber optic cable’s core. Use a fiber optic microscope with a good connector optical stage capable of 200X magnification for multi-mode connectors and 400X for single mode connectors. Digitally record your photos for future reference.

Fiber Optic Magnification

#3 - Fiber Optic Contamination Will (Probably) Occur

It’s nearly impossible to prevent contamination of fiber optic cable connections, even with the dust caps that come installed on your fiber optic cords and connectors. Common sources of fiber optic contamination include oils and dust, packaging material, and other work site debris. Wet reagent-grade isopropyl alcohol can be used for more stubborn contaminates on the ferrule surfaces if necessary (see the table below). With Legrand's strict manufacturing processes, fiber optic cable assemblies may be clean right out of the bag, but we still recommend that you always clean and inspect the ferrules before plugging in.

HFC: Hydrogen, Florine, Carbon

HFE: Hydrofluoroether

IPA: Isopropyl Alcohol

HCFC: Hydrogen, Chlorine, Florine, Carbon (Hydrochlorofluorocarbon)

#4 - Proper Physical Contact Of Fiber Optic Components Is Critical

Fiber optic contamination prevents proper physical contact which can cause scratches and pitting defects that lead to permanent damage of your fiber optic cable. Physical Contact(PC), Ultra Physical Contact (UPC) and Angled Physical Contact (APC) connectors rely on proper physical contact to achieve a low loss, low reflection optical connection. If there is a film or debris that causes an air gap on the ferrule surface, the insertion loss of the connector increases, and so do the reflections.

#5 - Dust Attracts Dust

Charged dust particles attract more particles. Because glass fibers are insulators, contaminated connector end faces will also continue to attract and accumulate more and more dust and debris. A clean fiber optic connector will appear pristine under the microscope and there will be no contaminants on the fiber’s surface, or damage to the core.